电动压缩机耐久试验台软件

电动压缩机性能耐久试验台软件

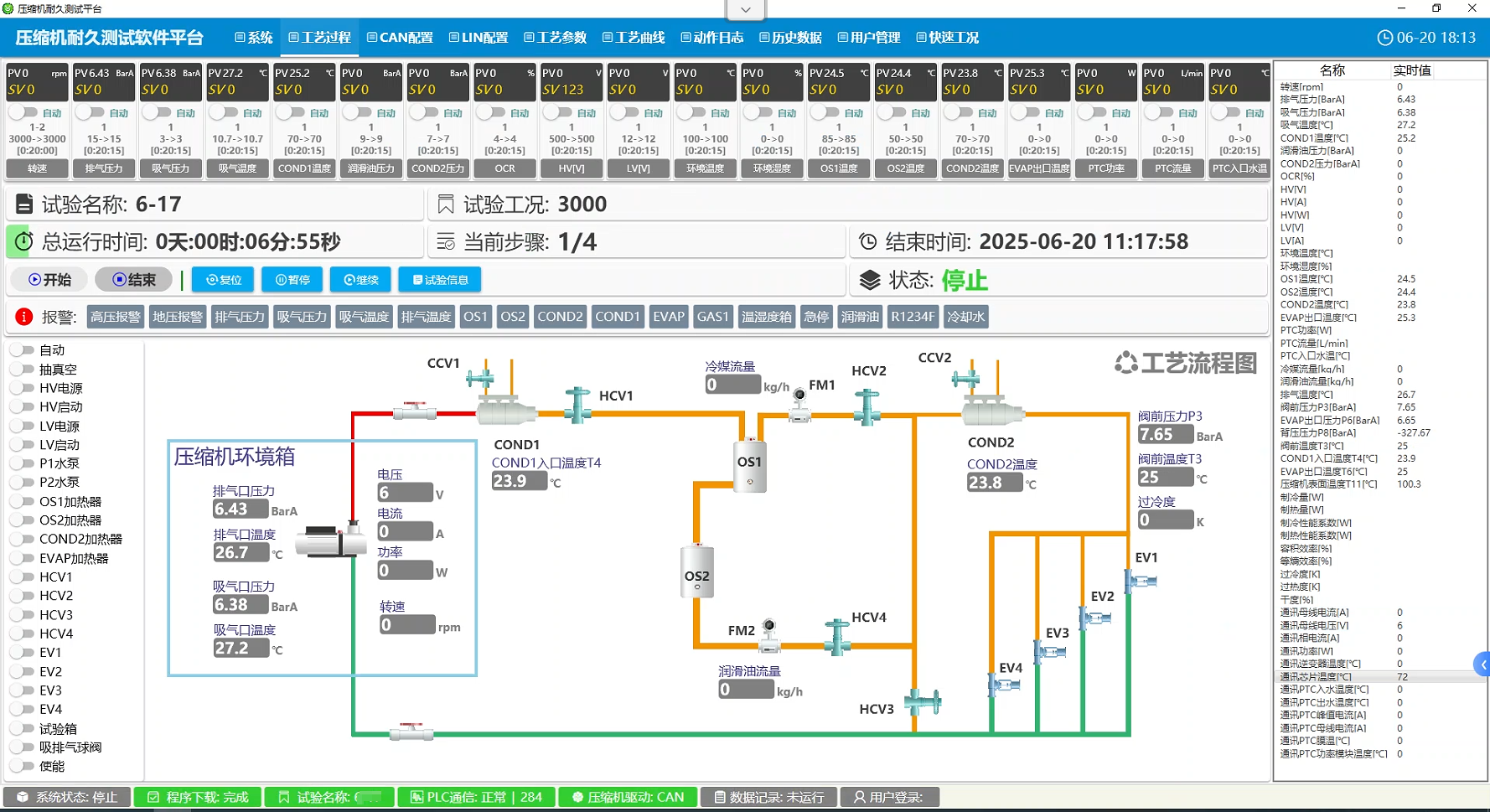

压缩机作为工业、汽车空调、制冷等领域的核心设备,其长期稳定运行直接影响到整个系统的安全与效率。为了保证压缩机在各种工况下的性能及耐久性,试验平台软件应运而生。该软件不仅集成了设备启动、参数设定、数据采集和报警管理等多项功能,还实现了自动化试验流程和远程监控,使得试验过程更高效、数据更准确、风险更可控。

2. 软件主要功能

- 2.1 试验方案管理

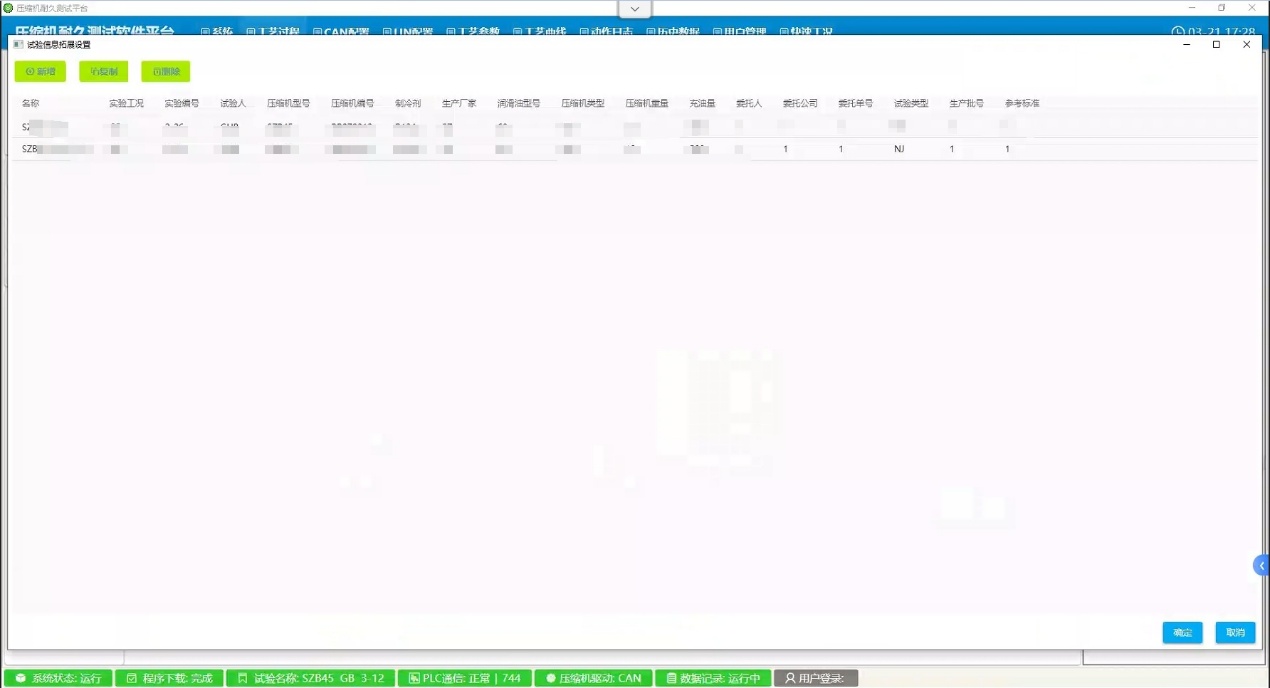

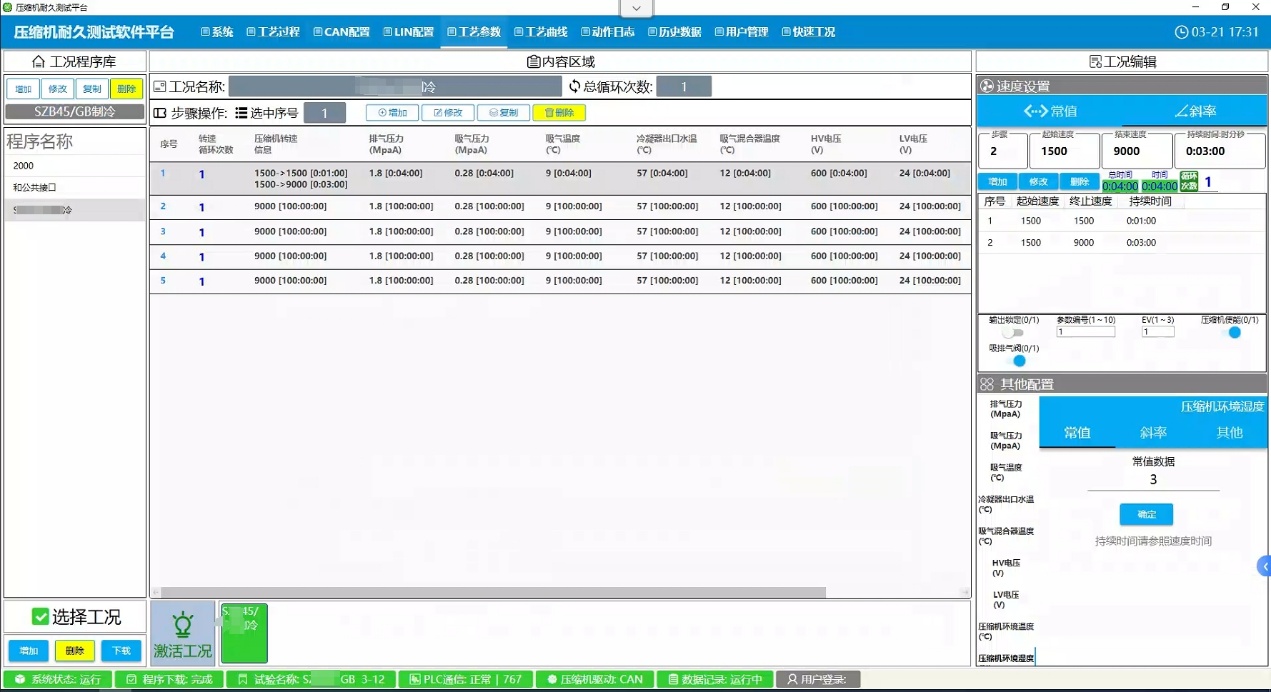

软件支持用户自定义试验方案,包括设定运行工况(压力、温度、负载等)、试验时间、采样频率以及停机条件。试验方案可保存、调用,方便不同压缩机型号的重复测试。

试验管理

2.2试验参数设定与方案管理

软件支持用户根据不同试验类型(耐久试验、性能试验)进行参数设定:

- 工况参数设定:包括高低压电源电压、温度箱温度、吸排气压力等。不同工况下的参数可以预设,并支持用户手动或自动加载相应的工况方案。

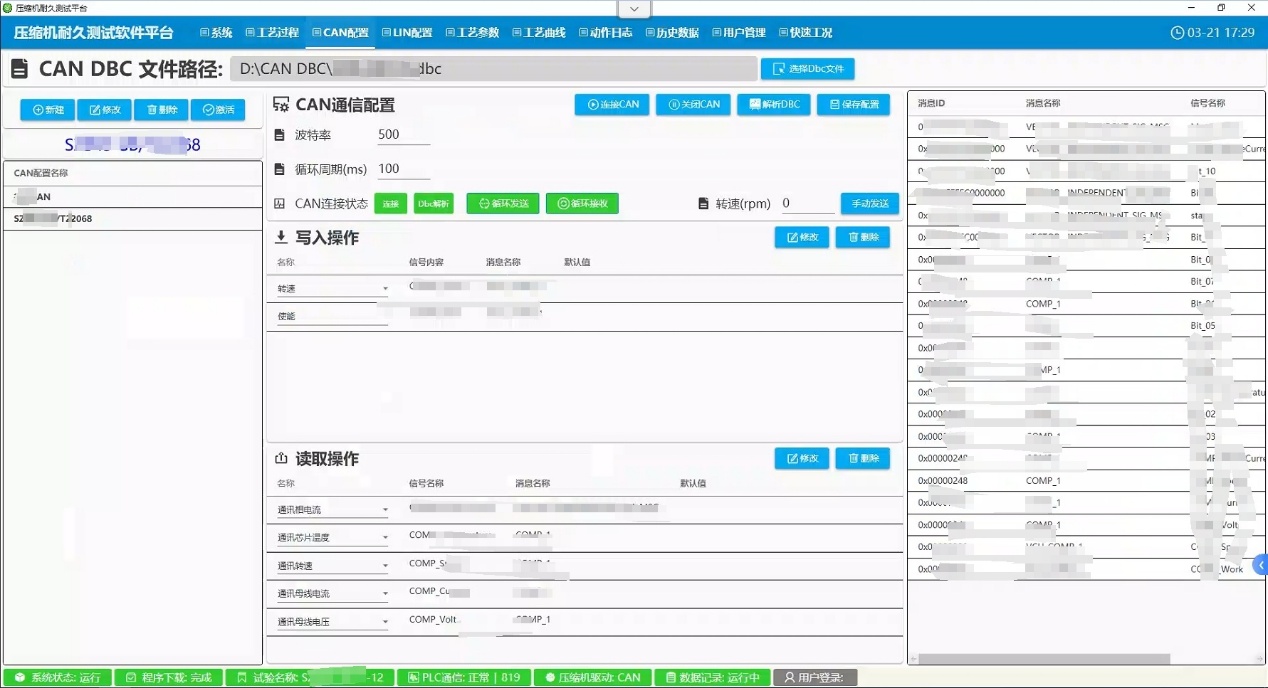

- 协议配置:支持压缩机LIN/CAN协议配置,通过加载LDF或DBC文件,实现与压缩机各参数信号的匹配和通信。

工况配置

2.3实时监控与曲线显示

软件界面直观显示各项参数数据:

- 仪表显示界面:实时显示电压、电流、温度、压力等关键数据。

- 曲线趋势图:各参数的实时曲线帮助工程师直观观察设备运行状态及数据波动,通过分页和自定义设置,方便对比和长期数据记录。

实时曲线

2.4数据记录与文件管理

平台软件具备自动数据存储和记录分割功能:

- 用户可自定义记录文件的保存路径和文件命名。

- 在数据量达到预设容量后,系统自动分割压缩文件,确保数据安全完整并便于后续查阅和分析。

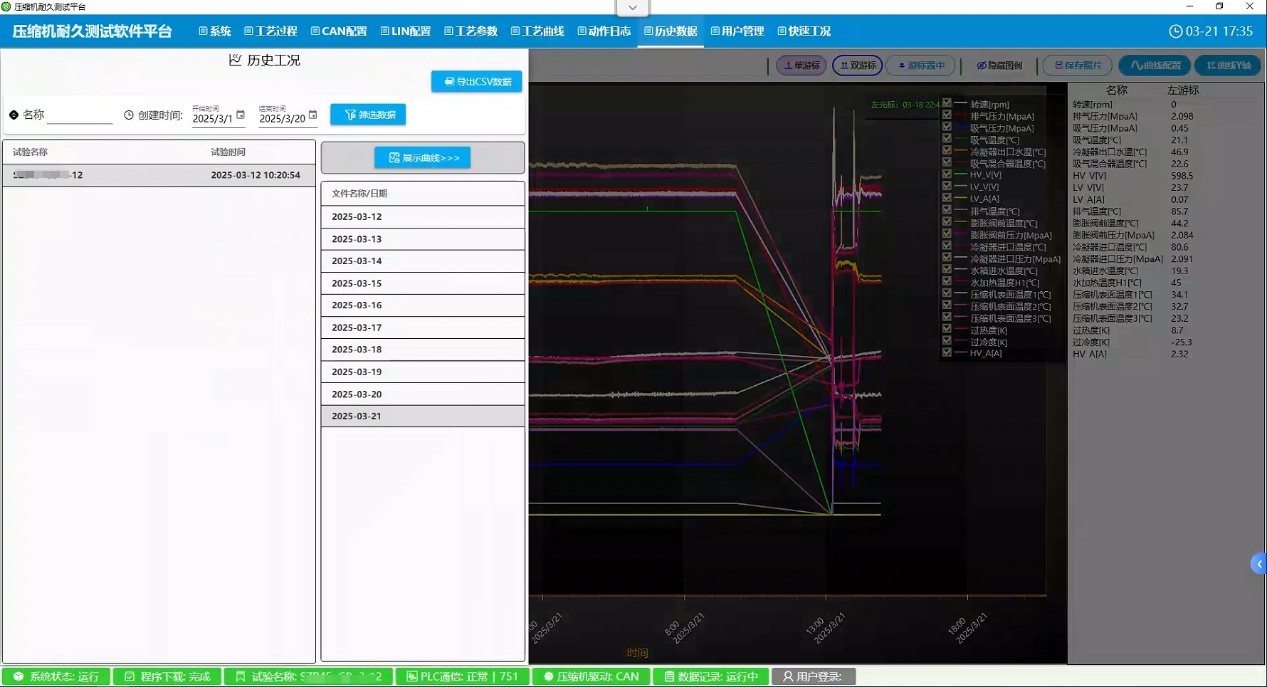

- 用户可以根据管理的工况调取任意时刻的历史数据并进行曲线绘制,方便用户查看,支持单游标、双游标、多参数Y轴分析、曲线分组、最大值和最小值及平均值分许等复杂功能

历史曲线和数据导出

2.5报警与故障诊断

为确保试验过程中设备安全,软件设计了完善的报警系统:

- 报警设定:对排气压力、吸气温度、油流量等参数设置上、下限。当数据超出预设范围时,可触发一级或二级报警,并自动记录故障日志。

- 故障模式分析:结合历史记录与实时数据,软件可以对潜在故障进行诊断,帮助工程师及时调整试验方案。

2.6高级参数与PID调节

为满足不同工况对控制精度的需求,软件提供了高级设定功能:

- PID参数设定:用户可根据实际试验需求选择不同的PID组,并对各项控制参数进行细致调节。

- 阀门输出范围设定:针对排气压力、吸气压力等参数,可设置阀门的最小和最大输出,确保试验过程中设备响应准确稳定。

3. 应用与优势

压缩机性能耐久试验平台软件在实际应用中具有以下优势:

- 自动化程度高:从抽真空、加注润滑油/制冷剂到试验参数设定、数据采集和报警功能,全流程自动化大大减少了人为干预的误差。

- 数据可视化:实时曲线和历史数据记录使得故障原因查找和性能趋势分析更为直观,为研发和质量评估提供有力支持。

- 安全性保障:多重报警机制及故障日志记录确保设备在异常情况下能及时采取措施,防止设备损坏或事故发生。

4. 结论

压缩机性能耐久试验平台软件不仅是一款功能丰富的测试工具,更是一种保障设备长效稳定运行的先进手段。通过对工况参数的精确控制、实时数据监控及智能报警诊断,该软件为压缩机行业提供了高效、科学的试验解决方案。未来,随着自动化与智能化水平的不断提升,此类平台将更加精准地服务于设备性能评估和质量提升。

欢迎沟通交流学习

Electric Compressor Performance and Durability Test Bench Software

1. Introduction

Compressors are core equipment in industrial applications, automotive air conditioning, refrigeration, and other fields. Their long-term stable operation directly impacts the overall safety and efficiency of the system. To ensure compressor performance and durability under various operating conditions, the test bench software has emerged. This software not only integrates multiple functions such as device startup, parameter setting, data acquisition, and alarm management, but also implements automated test procedures and remote monitoring. As a result, the testing process becomes more efficient, the data more accurate, and risks more controllable.

2. Main Functions of the Software

2.1 Test Plan Management

The software supports users in customizing test plans by allowing the setting of operating conditions (such as pressure, temperature, load, etc.), test duration, sampling frequency, and shutdown conditions. These test plans can be saved and recalled, facilitating repeated testing across different compressor models.

2.2 Test Parameter Setting and Plan Management

- Operating Condition Parameter Setting: Users can preset parameters for various operating conditions, including high and low voltage levels, temperature chamber settings, intake/exhaust pressure, etc. The software supports both manual and automatic loading of the corresponding operating condition schemes.

- Protocol Configuration: It supports compressor LIN/CAN protocol configuration by loading LDF or DBC files, which enables matching and communication with various compressor parameter signals.

2.3 Real-Time Monitoring and Curve Display

- Instrument Display Interface: The software provides a clear, real-time display of key parameters such as voltage, current, temperature, and pressure.

- Curve Trend Charts: Real-time curves for each parameter help engineers visually monitor equipment operating status and data fluctuations. With features like pagination and customizable settings, it is easy to compare data and record long-term trends.

2.4 Data Recording and File Management

The platform includes automatic data storage and record segmentation capabilities:

- Customizable File Management: Users can define the save path and naming conventions for recorded files.

- Automatic File Segmentation: When data reaches a preset capacity, the system automatically splits and compresses the files to ensure data integrity and facilitate subsequent review and analysis.

- Historical Data Retrieval and Analysis: Users can retrieve historical data based on specific operating conditions and generate curves. The system supports complex analysis functions such as single cursor, dual cursor, multi-parameter Y-axis analysis, curve grouping, as well as maximum, minimum, and average value computations.

2.5 Alarm and Fault Diagnosis

To ensure equipment safety during testing, the software is designed with a comprehensive alarm system:

- Alarm Settings: Parameters such as exhaust pressure, intake temperature, and oil flow can have predefined upper and lower limits. When these values exceed the preset range, first- or second-level alarms are triggered, and fault logs are automatically recorded.

- Fault Mode Analysis: By combining historical records with real-time data, the software can diagnose potential faults, helping engineers adjust test plans promptly.

2.6 Advanced Parameters and PID Tuning

To meet the precision control requirements under various operating conditions, the software provides advanced configuration options:

- PID Parameter Setting: Users can select different PID groups based on actual test needs and finely tune each control parameter.

- Valve Output Range Setting: For parameters such as exhaust and intake pressure, users can set the minimum and maximum output levels of the valves, ensuring accurate and stable equipment response during tests.

3. Applications and Advantages

The compressor performance and durability test bench software offers several practical advantages:

- High Automation: From vacuum extraction, lubricant/refrigerant charging, to test parameter setting, data acquisition, and alarm functions, the fully automated process significantly reduces human error.

- Data Visualization: Real-time curves and historical data recording facilitate intuitive fault diagnosis and performance trend analysis, providing robust support for R&D and quality evaluation.

- Enhanced Safety: The multi-level alarm mechanism and fault log recording ensure timely actions in the event of anomalies, thereby preventing equipment damage or accidents.

4. Conclusion

The compressor performance and durability test bench software is not only a feature-rich testing tool but also an advanced means of ensuring long-term, stable operation of equipment. Through precise control of operating parameters, real-time data monitoring, and intelligent alarm diagnostics, this software provides an efficient and scientific test solution for the compressor industry. With continuous advancements in automation and intelligent technology, such platforms will play an even more precise role in equipment performance evaluation and quality improvement in the future.